(Cylinder head install while waiting for missing lifter shims)

Quick head volume check. I used a small syringe to check how much fluid I could insert under the plexiglass. This time I used windscreen washer fluid for reduced surface tension and better results.

Mine seems to be slightly over 37cc’s, let’s say it is 37.5cc

Install head gasket, a Cometic 4166-030:

No, first chase head bolt threads. Slight surprise here, I thought the threads were clean. Full of crud and whatnot.

All the bolt holes ended up having a mixture of cutting compound and metal particles at the bottom, so I improvised a little. I tilted the engine on the cradle and stuck a neodymium magnet and sprayed the bolt holes with brake cleaner. Out came the grease and the metal particles.

This way I was able to make sure the metal particles didnt end up somewhere where they shouldnt be.

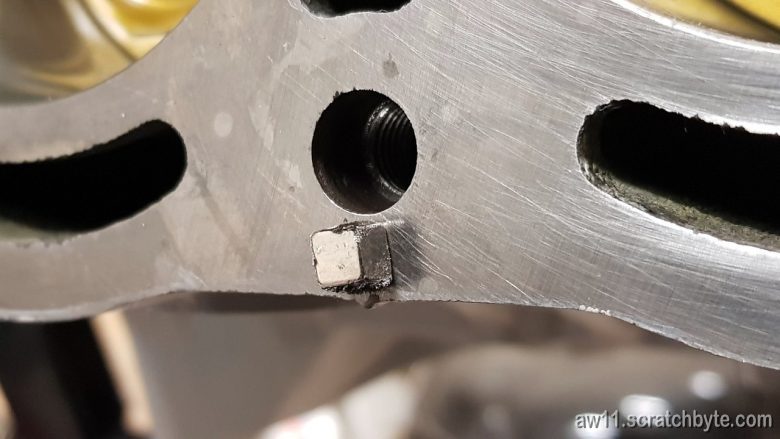

Metal particles stuck to magnet.

To make sure there weren’t any more metal around, I wrapped a magnet into paper towel that was wet with brake cleaner and wiped everything couple of times.

Studs inserted without much force (finger tight). Notice the first one on the right that is slightly shorter. That ends up under the distributor gear. While installing the nut on that one, it felt like the stud was way too short and it would be impossible to install cylinder head safely.

Precision job from ARP – the stud was long enough 😀

Fitting a head gasket – looks like the layers are separating and Im making a mess

Below torquing the nuts to 80Nm with plenty of ARP thread stuff.

Torquing felt scary. I had a awful awful feeling that something would go bang and I would end up with broken cylinder block and cylinder head fucked up beyond all repairs. Luckily, that didnt happen. 🙂

Leave a Reply