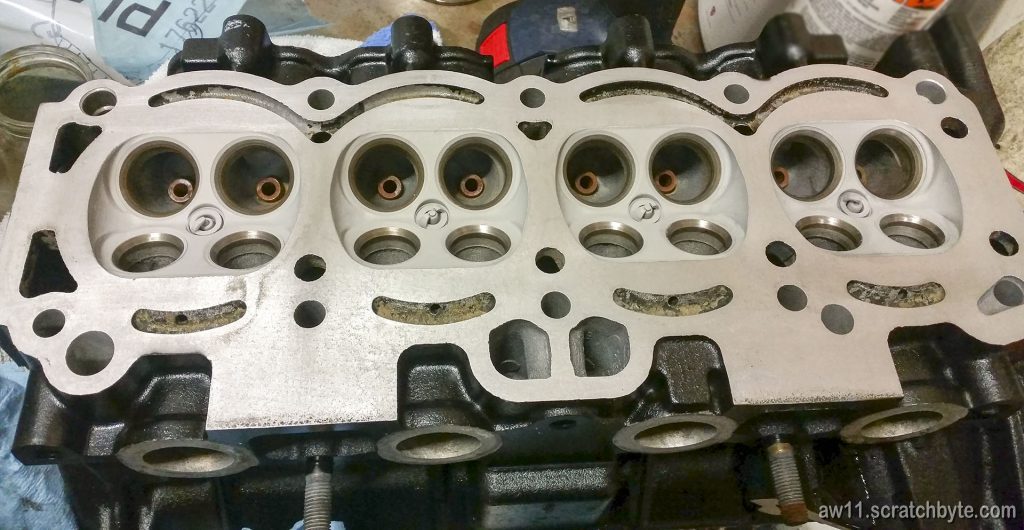

Before taking the cylinder head for oxidation removal, I tried (my best) to measure the head volume.

Better get some proper measuring equipment. My trusty 10cc syringe wasnt that accurate, but I got a result that was definetly over 36cc’s. I’m going to use 37cc’s until I get better tools. Next time I’ll use windscreen washer fluid or some cheap alcohol, because surface tension.

My syringe actually stopped at 38cc’s 🙂

Then measured both the deck height and stock 4A-GZE piston compression height. Deck height is 191mm and stock piston compression height 30.5mm.

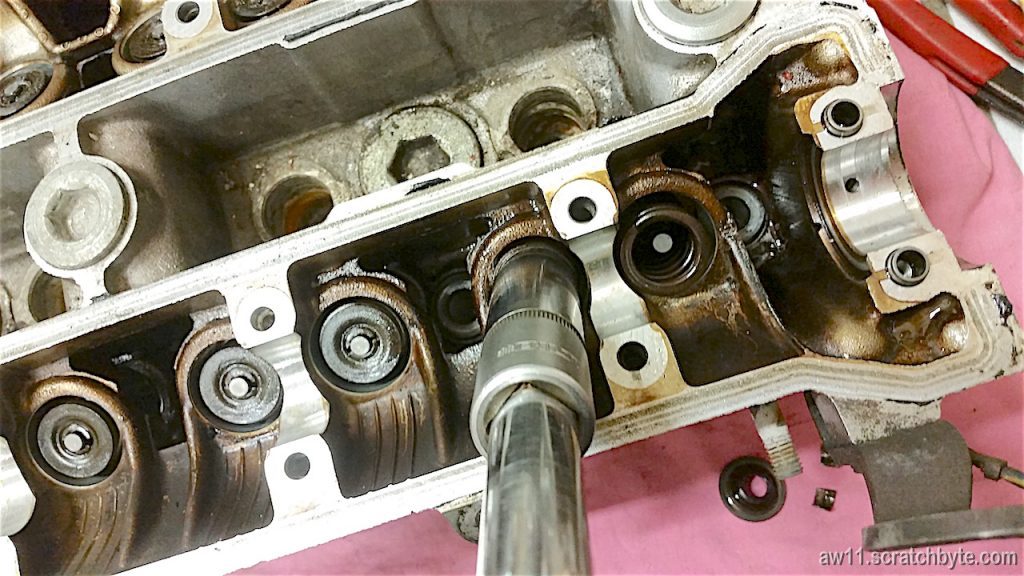

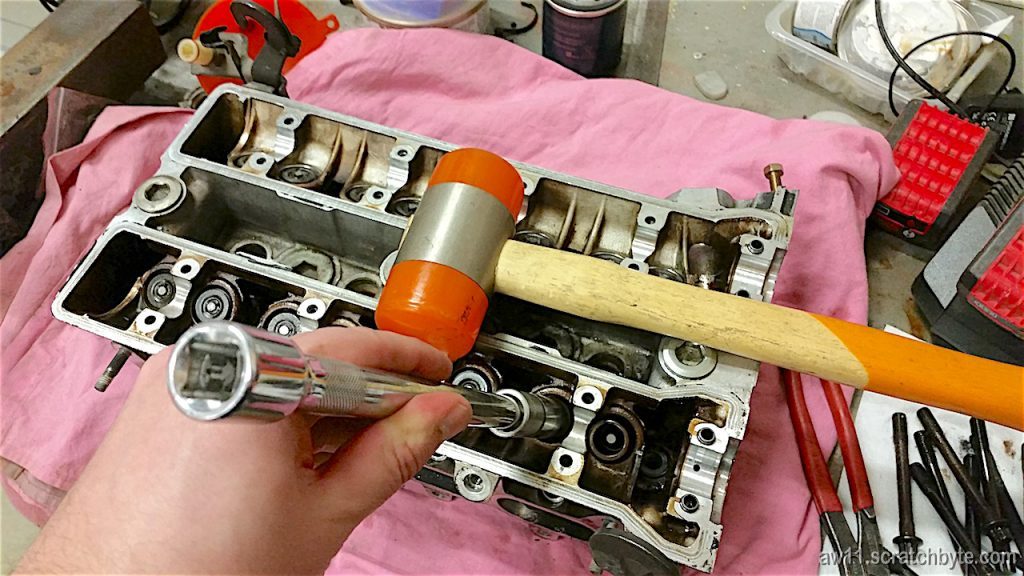

Valve guides are oxided as well. Or rusted. While getting degreased for the high-tech coatings, some of the alkaline washing liquid leaked inside and made a mess.

Compression calculations:

Seems that the stock pistons are level with the deck when at TDC. Stock 4A-GZE pistons have 30.5mm compression height and Wisecos have 30.68mm. Therefore Wisecos will poke 0.18mm above deck level.

- Bore: 81.5mm

- Stroke: 77mm

- HG thickness: 1mm

- HG bore: 82mm

- Deck clearance: -0.18mm

- Piston volume: 5.9cc

- Combustion chamber: 37cc

With these values the CR is 12.3:1

- 1mm headgasket – 12.3:1 CR

- 1.2mm headgasket – 12:1 CR

- 1.4mm headgasket – 11.7:1 CR

- 1.6mm headgasket – 11.4:1 CR

- 1.8mm headgasket – 11.1:1 CR

- 2mm headgasket – 10.8:1 CR

Well, the numbers are the same as before… and squish clearance sucks when head gasket is thicker than 1mm.

Wiseco, you suck.