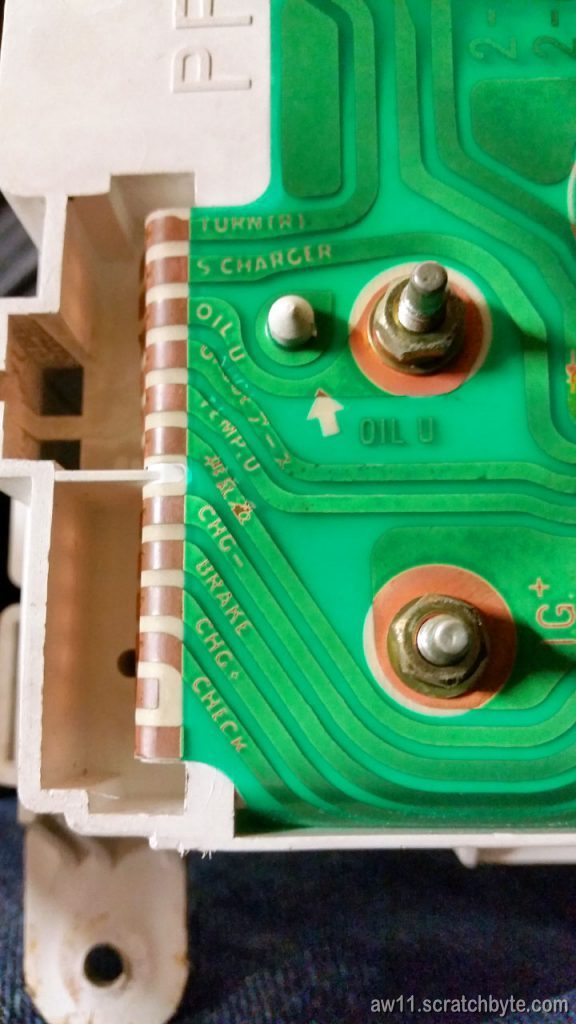

Normally the Toyota tacho doesn’t work with aftermarket ecu. The Toyota tacho needs a high voltage pulses from coil to work. I didn’t want to build a voltage booster from modified relay or anything like that, which meant I had to look into the tacho electronics.

I googled a bit, read some forum posts about toyota tachos and then decided to try something. Guessing is sometimes good – I guessed the first resistor after the signal terminal has something to do with this thing.

I bypassed the first resistor completely and the tacho came into life. Simple and nice.

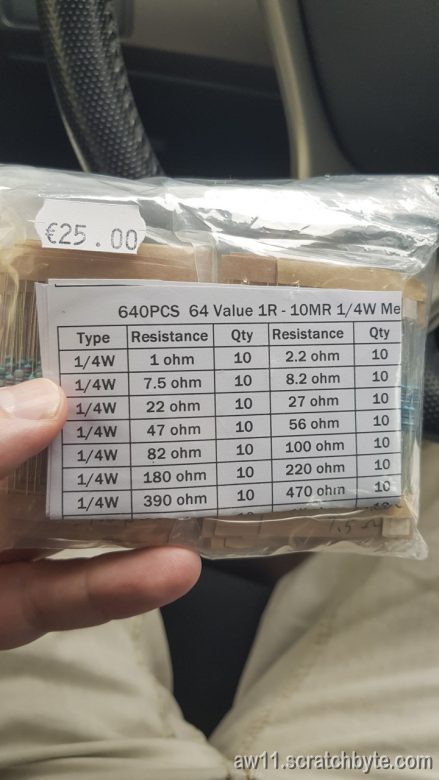

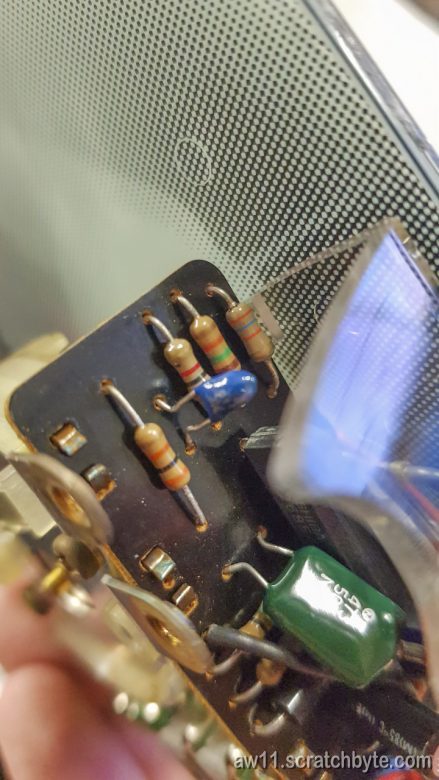

Note: following resistor values worked for me – check yours if you’re doing something similar

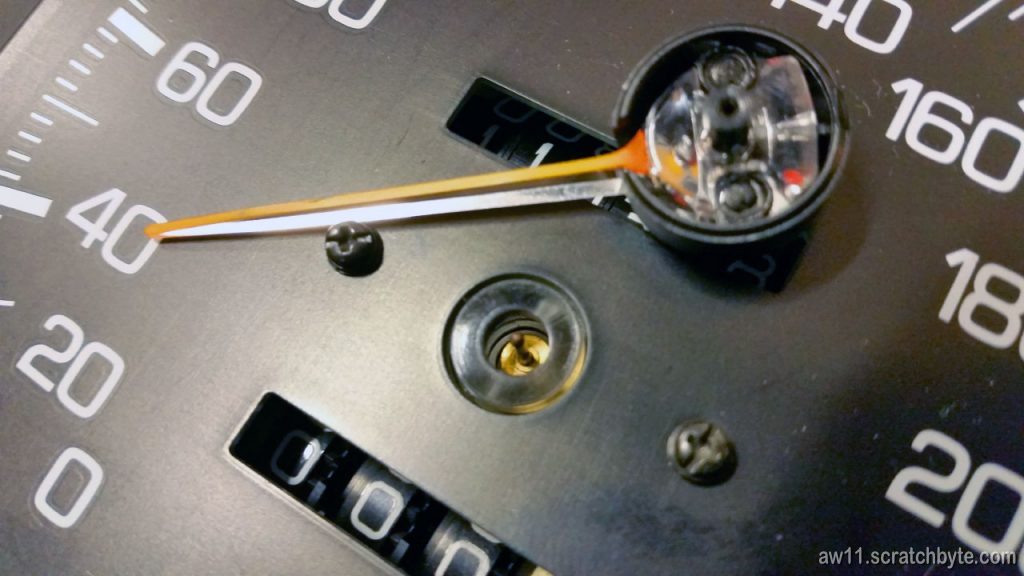

I didn’t want to tear my dash at this point so I tested with the 10k tacho

I measured the first resistor and it was in the 30kohm ballpark. I thought there should be some resistance in the signal path so I had to find out what the resistance needed to be so it would work with aftermarket ECU signal.

The easiest way was to solder a resistor parallel to the original to lower the total resistance.

I bought a pack of random resistors and a linear potentiometer to find out what I need.

The resistance where the Toyota tacho started to work was 15kohm, which meant I needed a similar 30kohm resistor parallel to the original

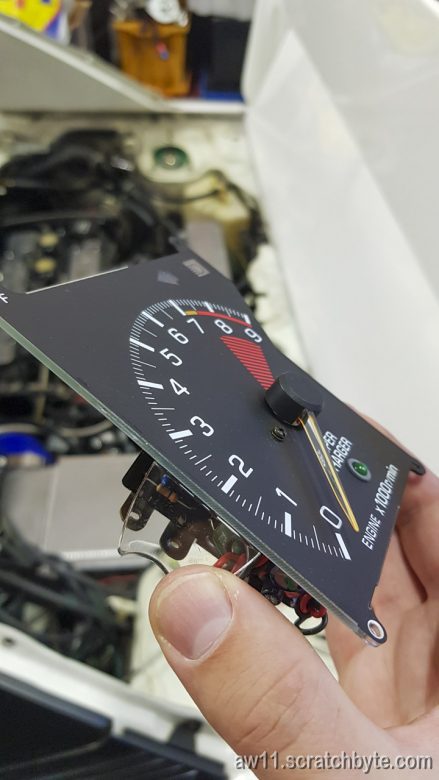

Tore out the stock tacho

…and soldered a second resistor parallel using the stock resistor leads

It worked. Stock tacho works now.