I reached the turnaround point! Now I’m putting things back together and going towards working engine 🙂

There were problems, though.

New ACL bearings coated in solid molybdenium for extra slippery and first start safety.

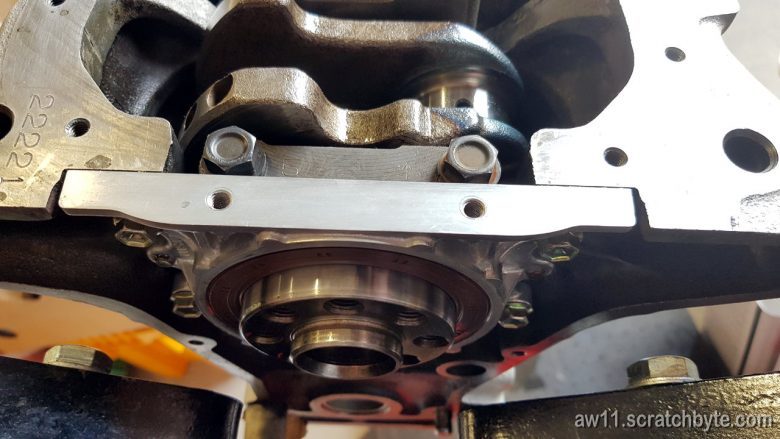

Crank test fit. Stock bolts and oil pump.

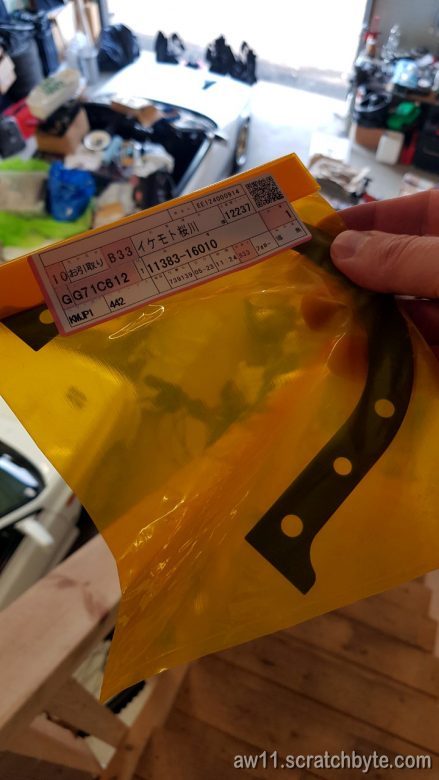

Rear main seal bracket and the seal itself. Below, the gasket for the bracket.

Seal in place. Left side you can see the 22221 number which indicates the crank line bore sizes.

Glueing the crank girdle to place with Permatex Supra Grey. Main bolts swapped to ARP studs and nuts.

This is where the problems started.

I left the gasket goop to dry for an hour and came back to tighten the main stud nuts. I quickly glanced the ARP installation procedure and thought that it is funny how ARP recommends the tightening torque to be the same as Toyota stock, which is 60Nm. Tightened everything in three steps and then I tried to rotate the crank. It wasnt turning as freely as I hoped.

I checked everything. Removed nuts, removed studs and checked everything possible. Tried tightening again to 60Nm but no dice. There still was a point where the crank felt like it was stuck. Then I read the ARP installation document again and to my horror ARP recommendation wasnt 60Nm, instead it was 60ft/lbs, which is around 80Nm.

The crank seized totally. It only turned a bit when I helped it with the biggest rubber mallet I could find in our garage. Shit shit shit fuuuuuck.

hi mate, you say your crank seized up when you torqued it down to spec?, it happened to me too when swapped to ARP main studs. the studs diameter is slightly bigger then the oem, so when you tighten the 3rd main cap, the one with the thrust bearings, the cap gets tweaked and jams up the crank, you need to bore out the holes slightly. you can test my theory by torquing down all the other main caps first and see if the crank spins or replace the 3rd cap with the oem bolts. nice write up on the… Read more »

Yeah, with toyota spec (60Nm) I could still turn it, but it didnt feel good and when torqued to arp spec (80Nm or 60 lb/ft) it seized completely. I’ll check the main caps again, but I think mine have slightly bigger bores than the stud dia. I would have noticed something odd with cap studs because I took everything off (and put everything back in again) maybe twenty times when examining what caused the seizing. 😄 Im not sure if that theory needs any testing, either way Im not going to deviatd from the tightening pattern what toyota repair manual… Read more »

Oh, I almost forgot! Thank you for your comment!

that’s fair enough, it can get a bit scary when it comes to the motor. did you use plastigage to test the main baring tolerance? in my experience it was not the main bearings deforming or squeezing to tightly, it was the thrust bearings what was jamming the crank. if you dont like my previous idea and you have a dial indicator you can use it to test crank shaft endplay after each torque step and see if it decreases.

Yeah, I did use plastigauge plastigage to check that I could use non-toyota stock size bearings – also, my machinist checked my bearings after they got coated and they were all between 2.001mm and 2.005mm. They should be good. I can only throw in educated guesses what has happened with the thrust bearings when the main cap got tightened… as you said that you had badly machined bore holes, which must have contributed the thrust bearings being pushed against the crank. There is also the possibility where the torsional force applied to main cap bolts forces the main caps into… Read more »