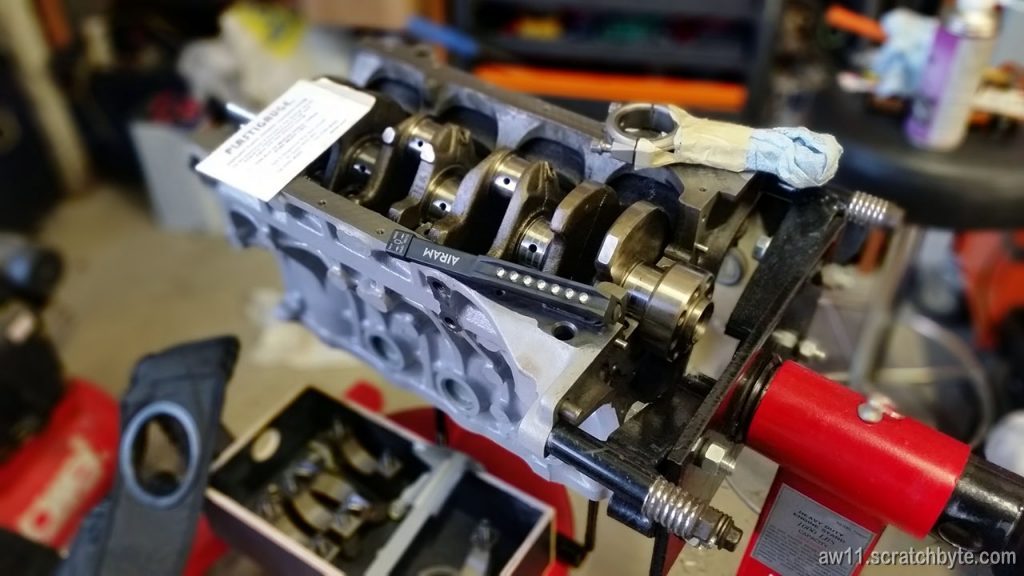

After the crank got stuck, I disassembled everything:

Bearings looked still good and the molybdenium coating was not affected.

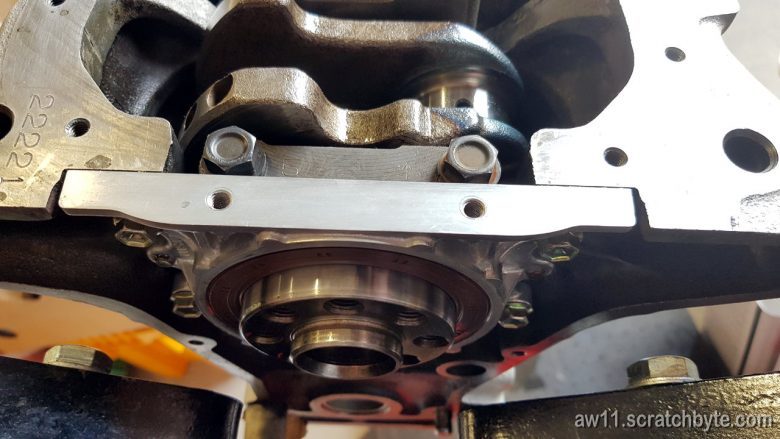

Little bit of measuring – picture below is staged 😀

While having the girdle plate on and everything tightened, the crank bore shrunk to 51,98mm. Didnt expect to see chunks of steel deform so much that the crank line bore would be out of spec (it should be 52mm)

Well, this meant a trip to machinist. Assembled everything back and made sure that the block and girdle were ready for the crank line honing.

Before honing:

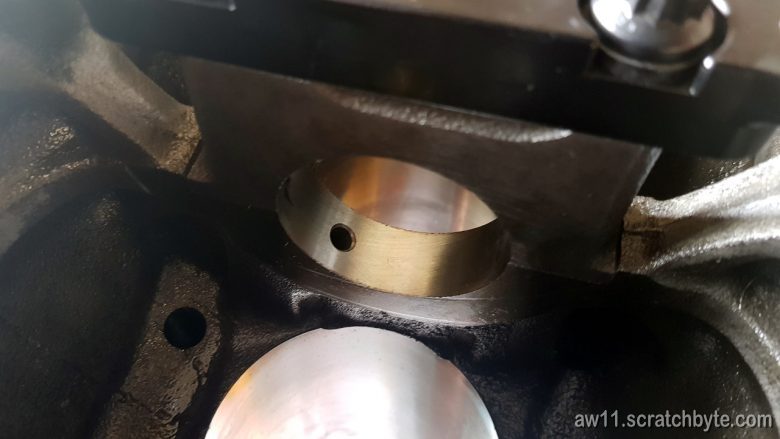

…and after honing:

Plenty of cleaning ahead, but the machinist said that the inside diameter is now 52.03mm.

The crank was also checked for straightness. Weirdly enough, it was 0.03mm out of straight, but now only 0.02mm. For some reason being stored for a year made it little bit more straight 😀