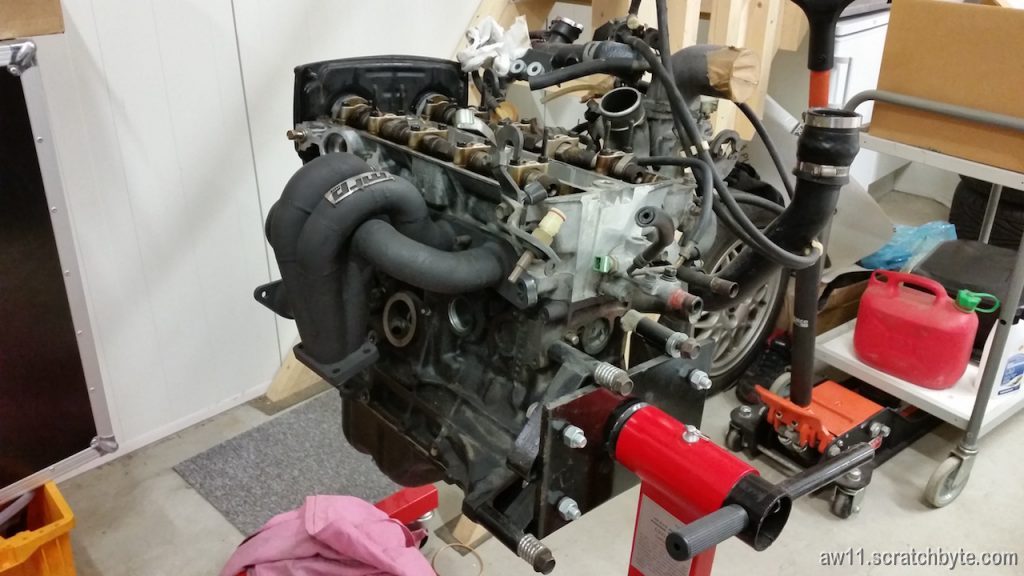

As much information as possible about toyota 4A-GZE 365cc injectors. This post will get some updates later.

- Low impedance, found a web page claiming 3.4Ω, another one claiming 2.9Ω. Better measure mine.

- NipponDenso built

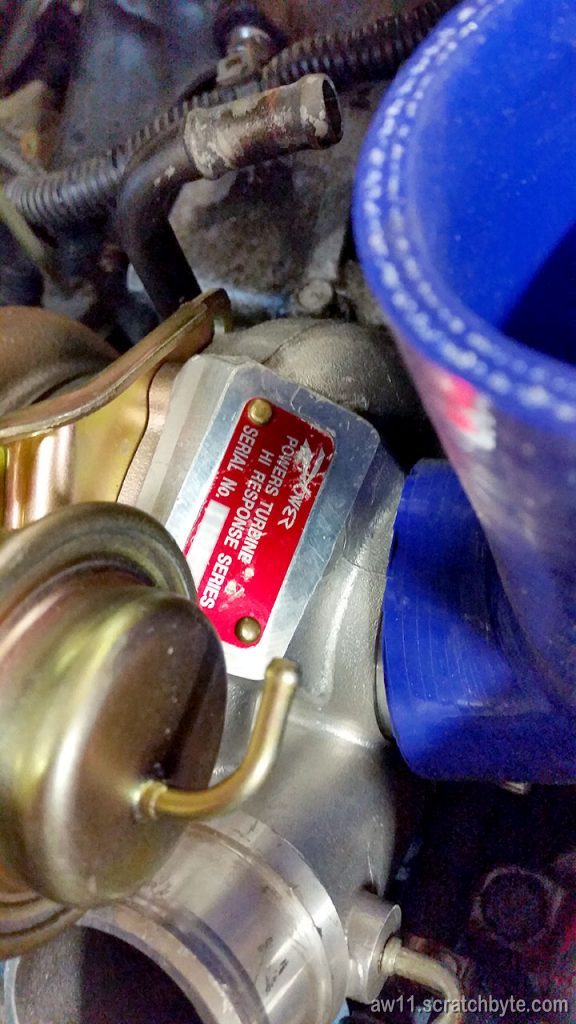

- Connector is surprisingly NipponDenso (Sumitomo) low guide connector.

- They’re red 🙂

- 365cc – 3bar, but I dont have the normal 4A-GZE AW11 fuel system pressure available. I’m guessing the pressure might be around 2.5bar and actual maximum somewhere near 300cc, maybe even less.

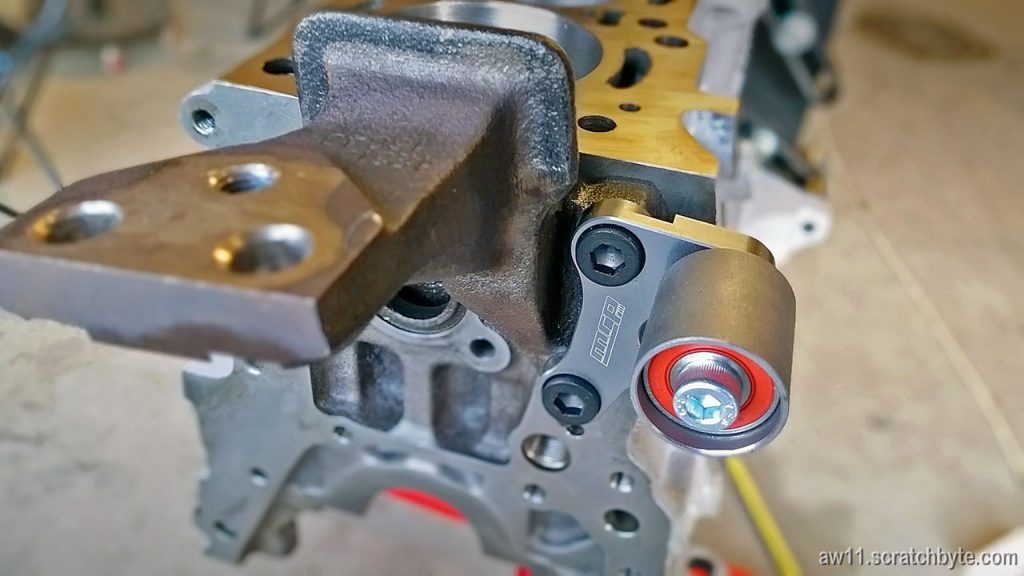

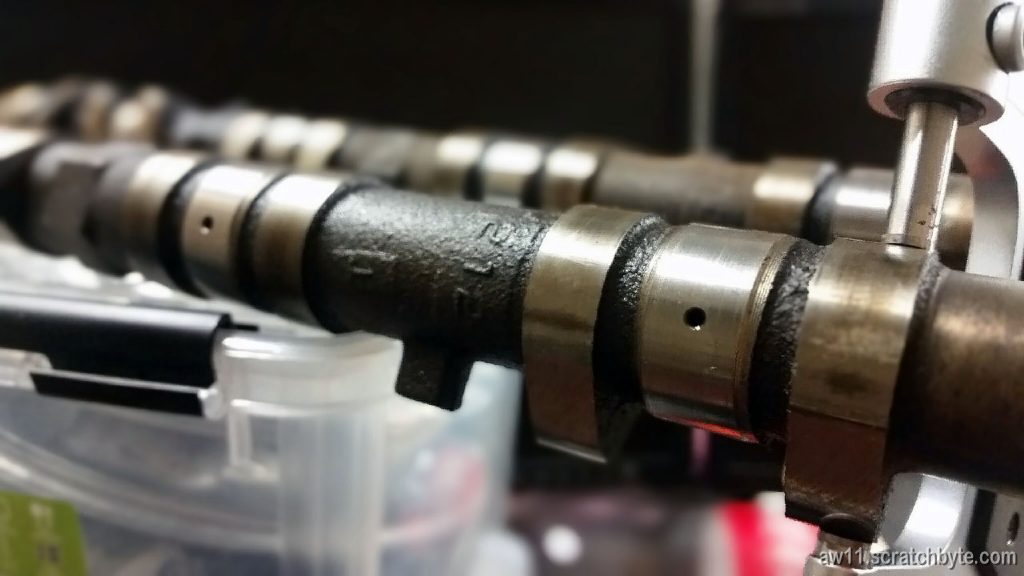

Nozzle. This type might do twin stream to both intake channels.

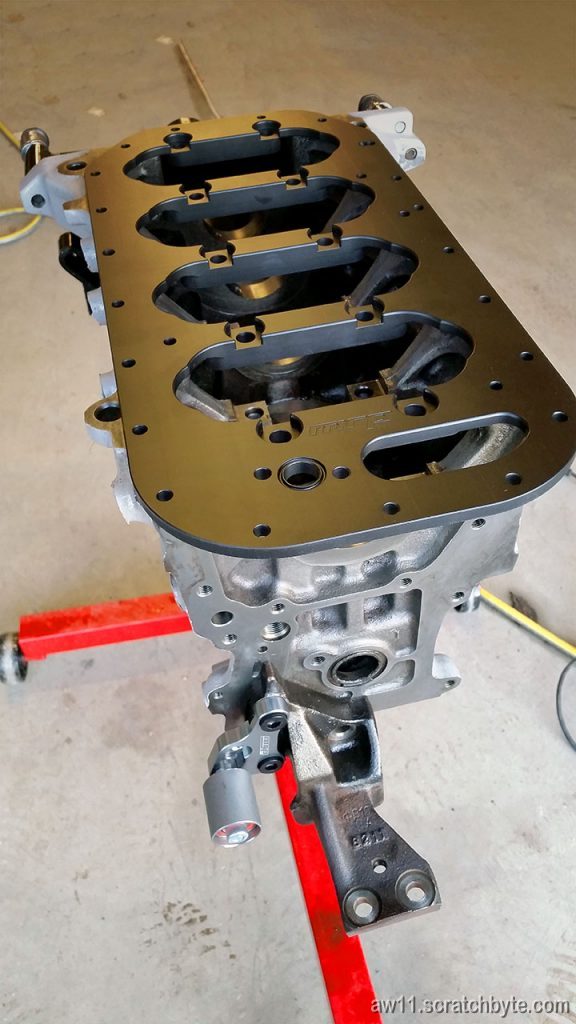

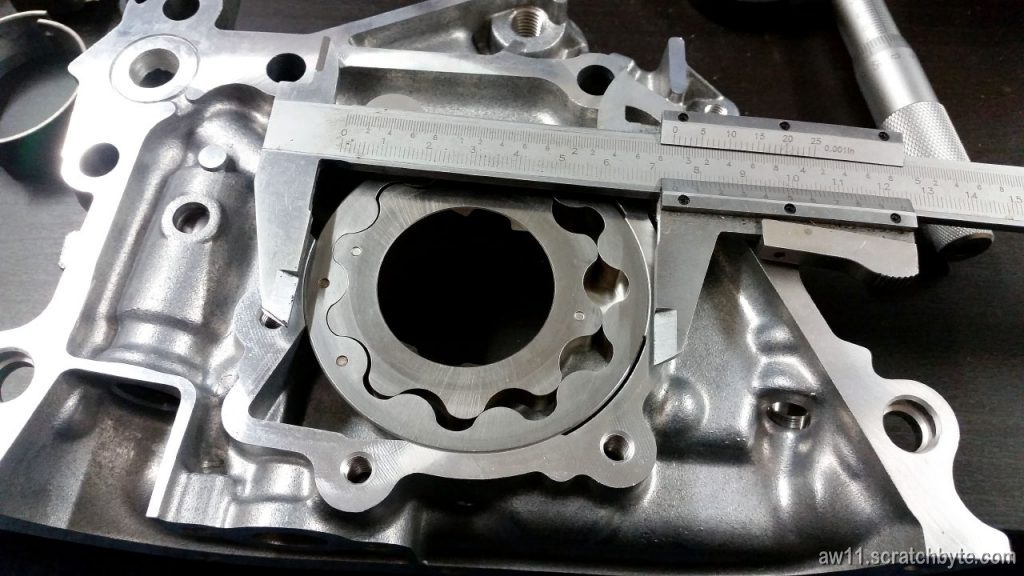

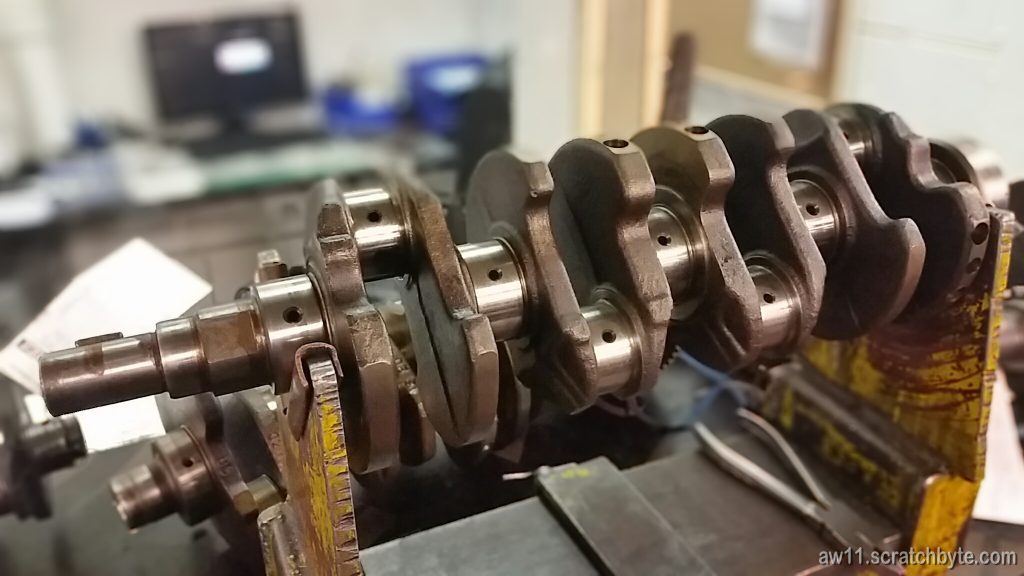

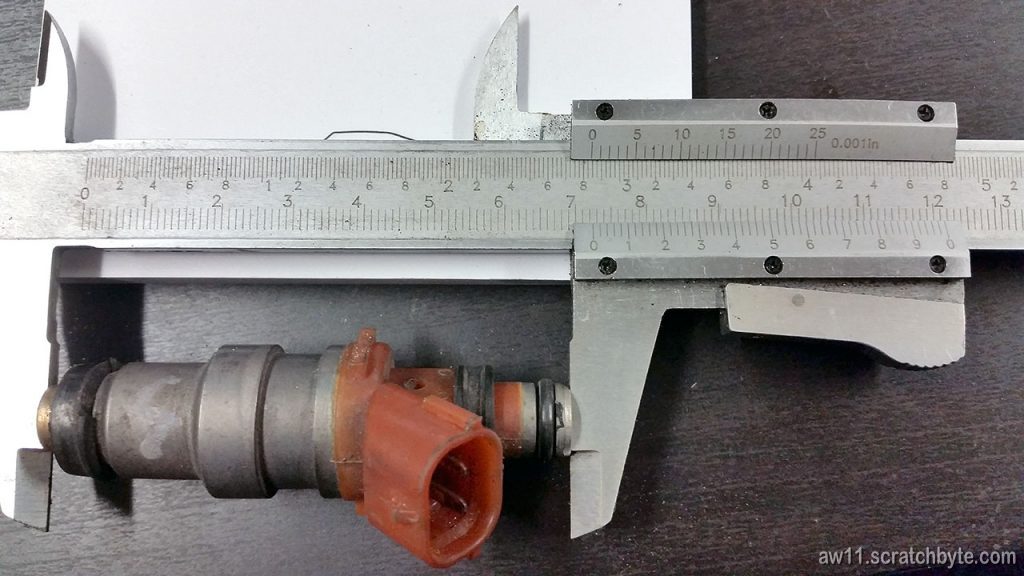

Bottom seal diameter is around 16mm. I forgot to measure the height.

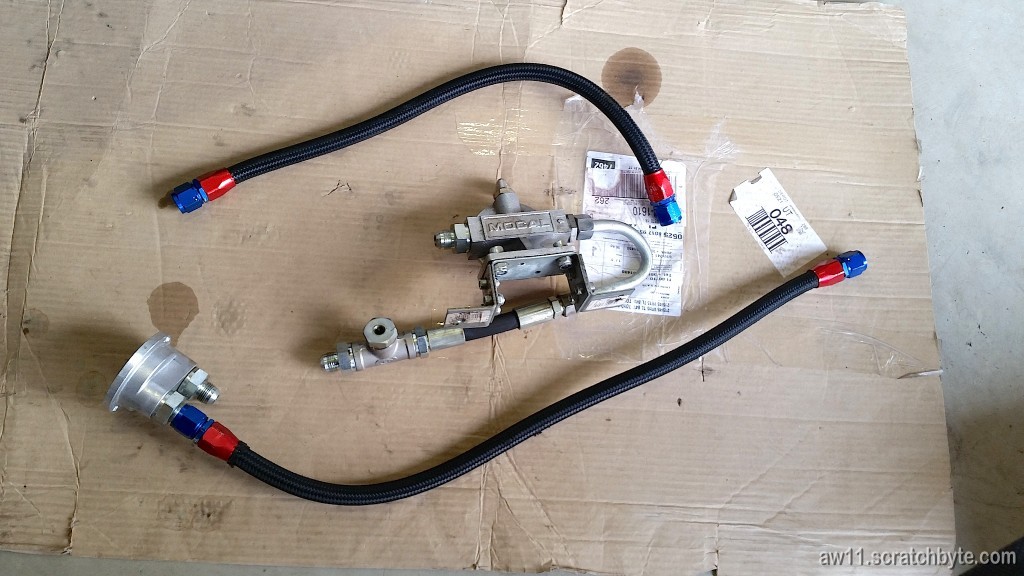

Toyota calls this part insulator, injector vibration. Part number 23291-41010

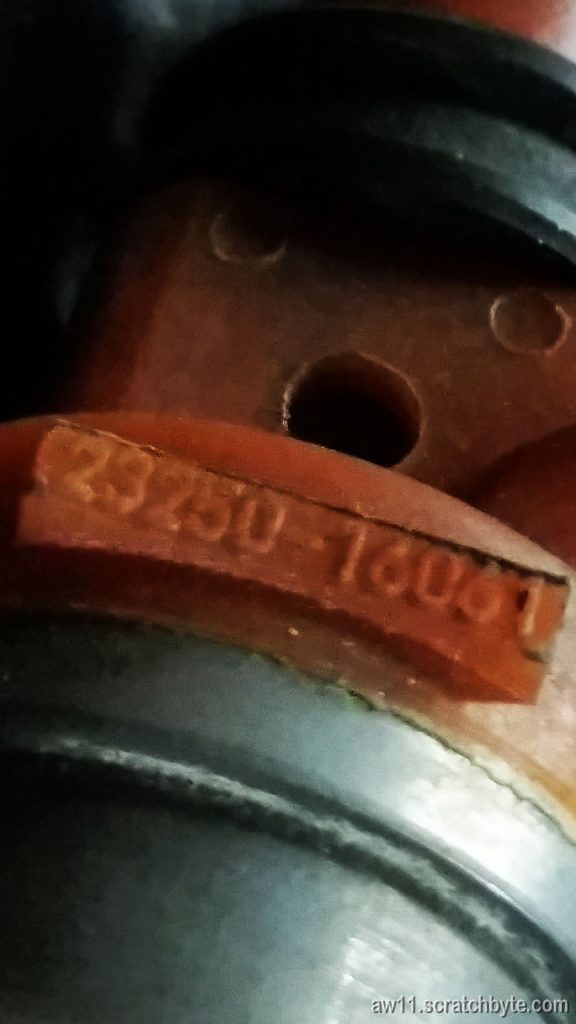

Part number is 23250-16061. There are some differences between injectors, mine seem to be marked white so the complete part number for my injectors is 23250-16061-04.

Older 4A-GZEs had 23250-16060 injectors. I’m unsure how they differ from these.

From bottom seal center to upper seal center (c-to-c) is around 62mm

Side view

Total length is 72,5mm

Connector. Dirty AF.

The rubber thing next to connector and “below” top o ring should be Grommet (For fuel injector) – part number 90480-13005.

The widest point is 21mm

Nozzle diameter is 10,4mm

Another nozzle picture

Top o-ring diameter is 11,5mm. Toyota calls this one Ring, O (For fuel injector) – part number is 90301-07001.

Thickness is 2mm

The other wide bit at the bottom of the injector, 16mm.