Some progress with the MR2 🙂 I got parts for the gearbox linkage and I installed most of them, just to test how the stick shifter works and feels. There is some looseness with the shifter base, but I think that will be easily fixed.

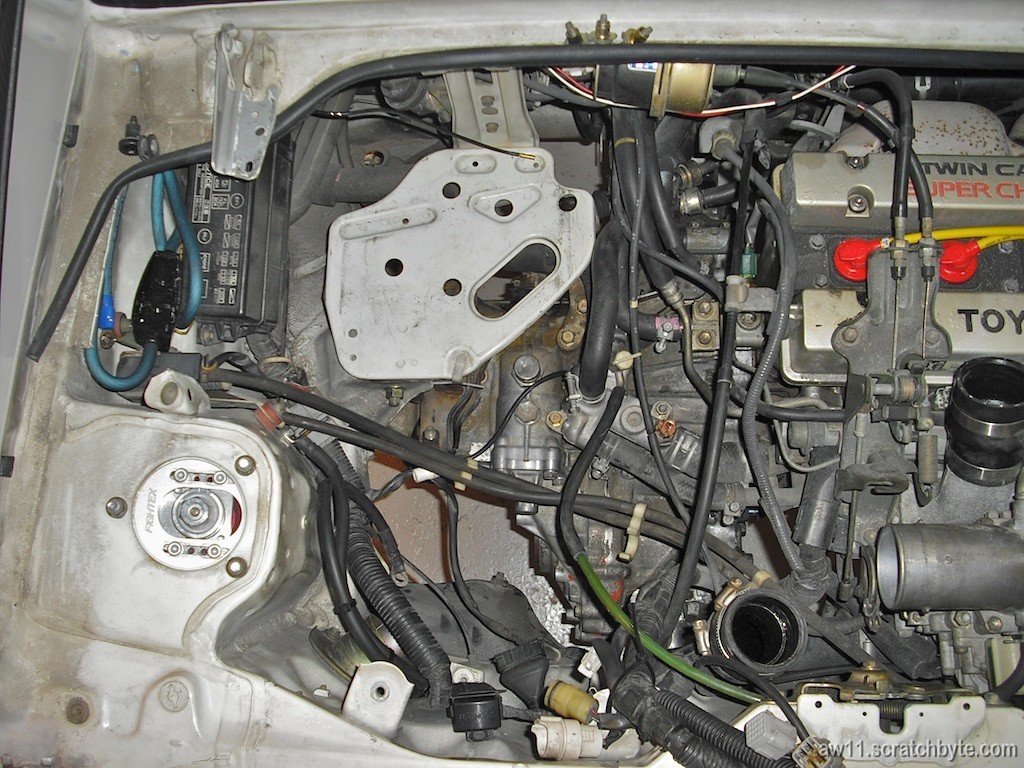

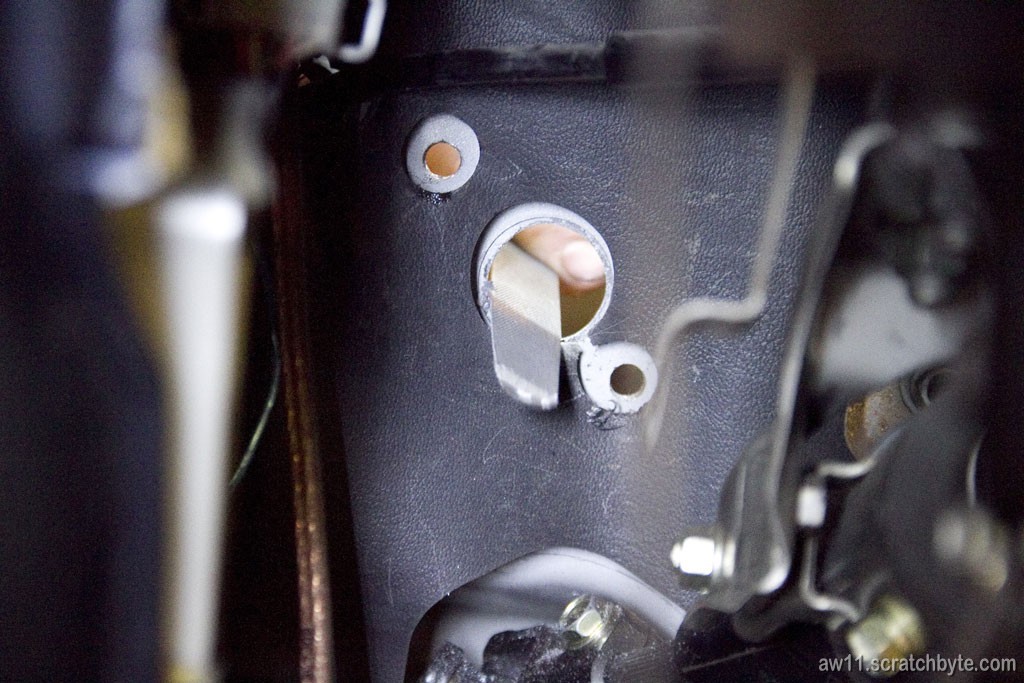

Starter motor was easy to install, just two bolts (39 Nm of torque) and that was it. 🙂

After starter motor I installed everything that was missing from the clutch, mostly lines around release cylinder and some other stuff.

I also reworked some parts of the clutch hose and rerouted it. I found out that my original route was not that good if you wanted to do something to it later. The hose is now attached to the original clutch line brackets and is covered with clear vinyl tubing at some corners. (pictures later)

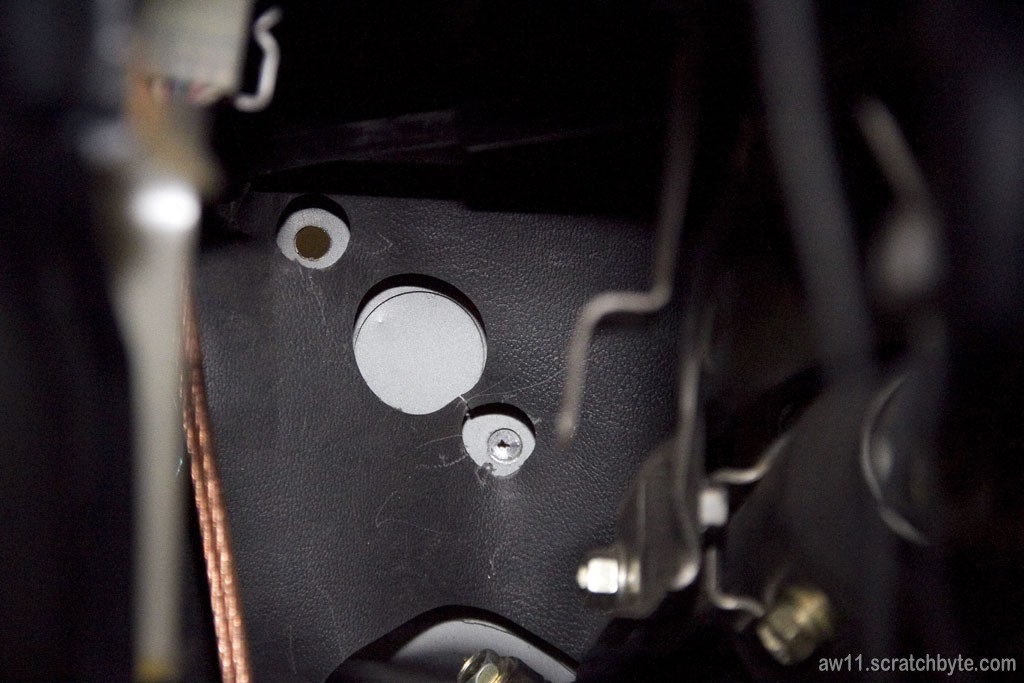

When everything looked good, I was ready to bleed the clutch. Some small leaks, but tightening fixed ’em.

Bleeding was quite easy, but afterwards I found out that while I pressed the pedal it didn’t do anything. Release cylinder just sat there and didn’t move at all. I think it must be the master cylinder, so I need the rebuild pack for it.

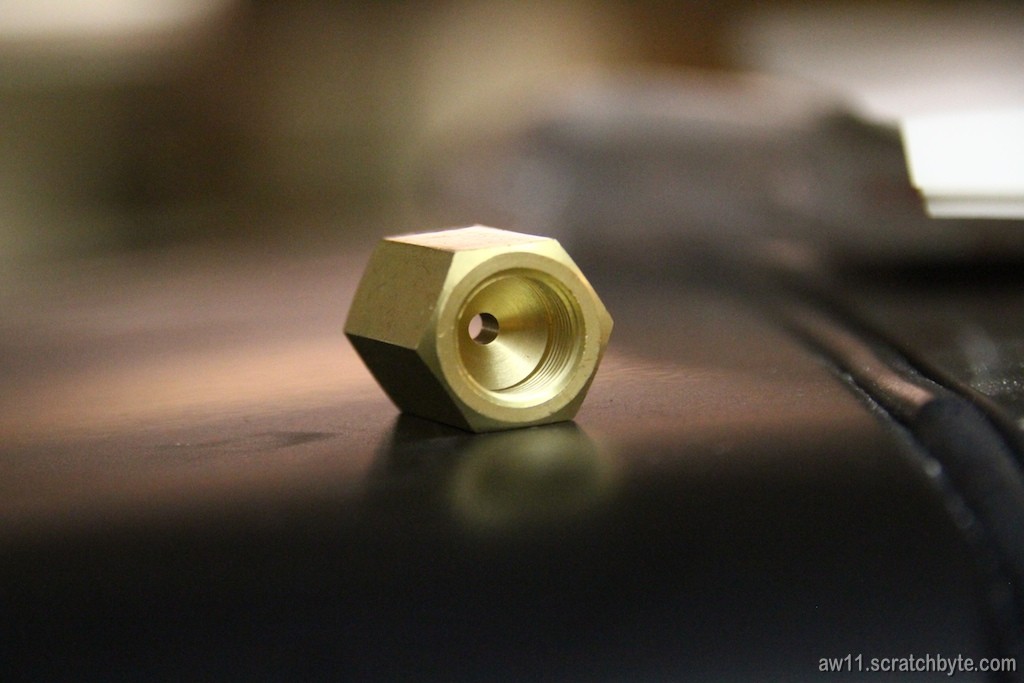

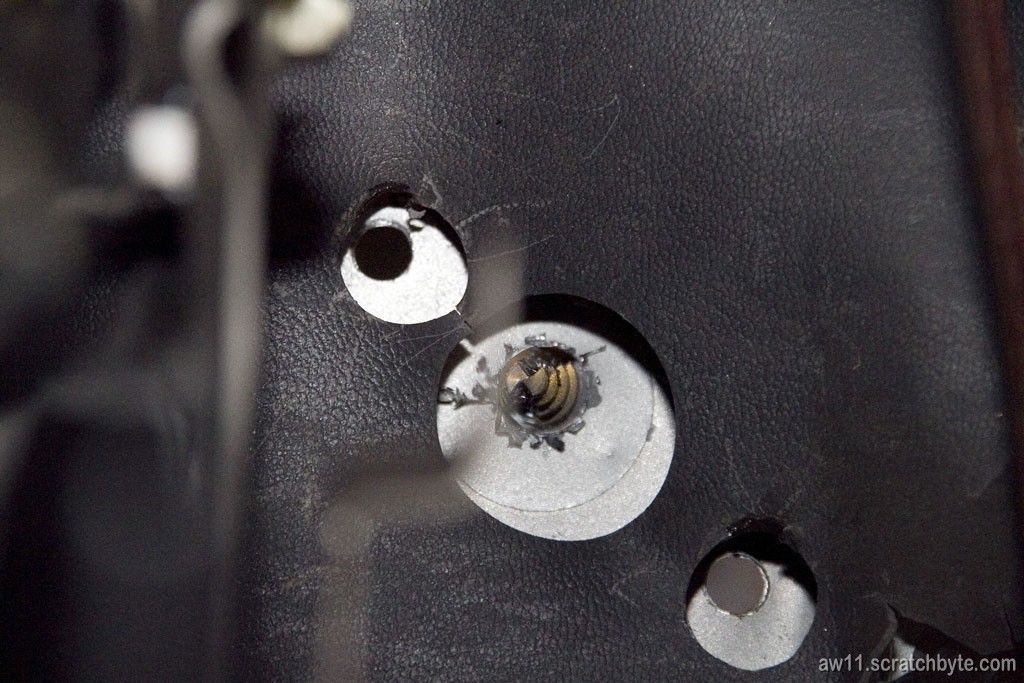

I’m still missing (I have no idea where it went) one of the big bolts which attaches the gearbox to the block. A/T and manual have different bolts and the biggest one for the M/T is not available anymore. Part number is 90119-12109 and measures for the bolt are as follows: 12-1.25P x 102-30

Maladar is still sick. Get well soon!