Ok, this thing had bothered me some time. One of the intake pipes had been spraying oily mist around the engine bay. Being lazy, this took me some time to fix.

There is a second problem too. Every time I floor the car for a longer time, the whole car smells like belts were slipping, but it goes away pretty quick. No idea what that is.

Meh. A mess and I spent a whole day cleaning and sweeping.

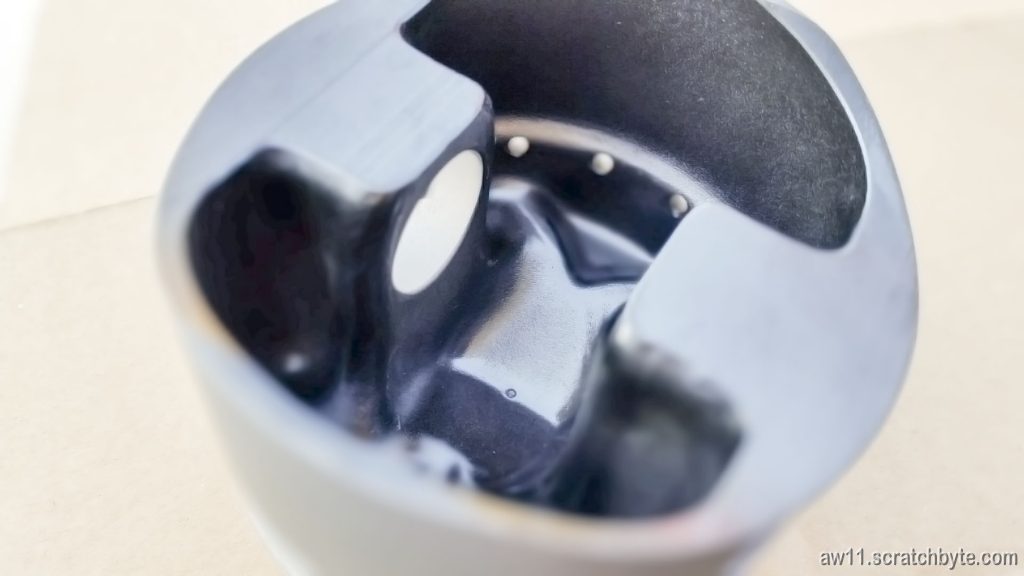

First peek into my custom intake plenum! Parts are from a different prototype, but they were good to get some needed measures.

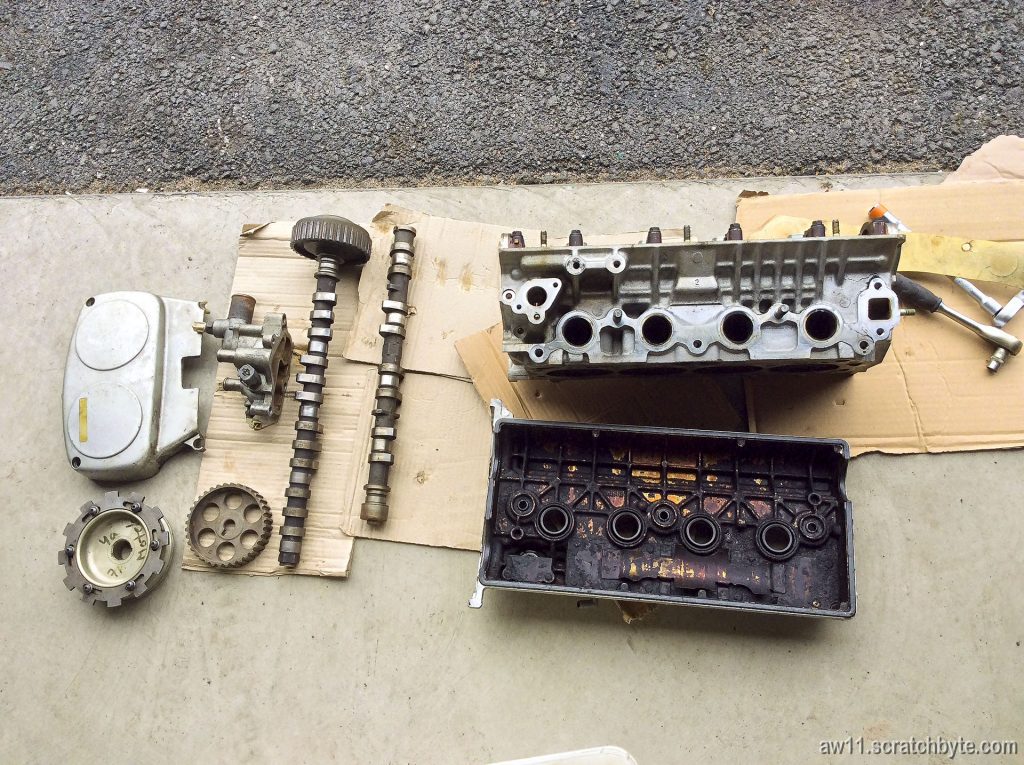

Pile of bits and parts. Trying to keep everything in order.

Widric the dwarf viking came to garage to check some wheel options.

His stock 16″ wheels from the older Impreza didnt fit over the 4/2 brakes, so we tested the Advan Sienas as well.

Advans were spot on. Except the bolt pattern.

Widric has a set of 5×100 -> 5×114.3 spacers, but alas, the wheel poked out too much. You can see the frustration on his face 😀