Ok, easy start. Jack the car up, remove rear tire.

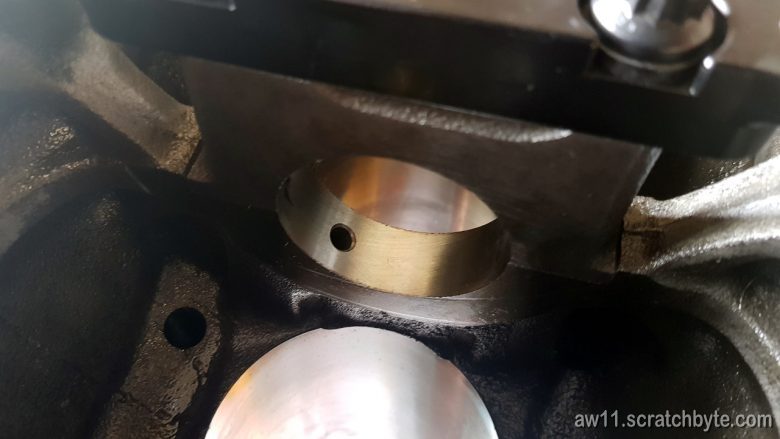

First look from underside after removing AC compressor. Oil mixed with dirt everywhere. I better check my oil level, feels like my engine has more oil outside than inside.

The AC compressor was also covered in oil. I found it on the bolts too.

And the lower alternator bolt. Completely covered in oil. It seems my engine oil would work wonderfully as penetrating oil.

Broken one on the left

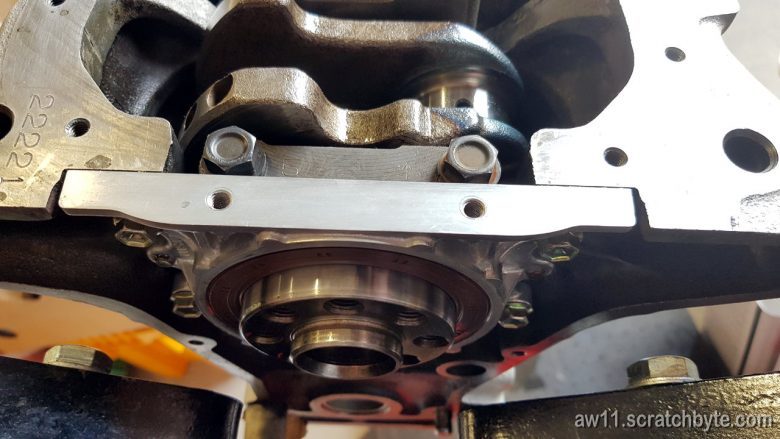

Under all that muck this thing looks surprisingly good. I wonder if this really is a 30-year old alternator. The pulley (and therefore the whole thing inside – the rotor) was rotating very easily. Definetly not a bearing problem.

Toyota part number is 27020-16130 and Denso part number is 121000-2500

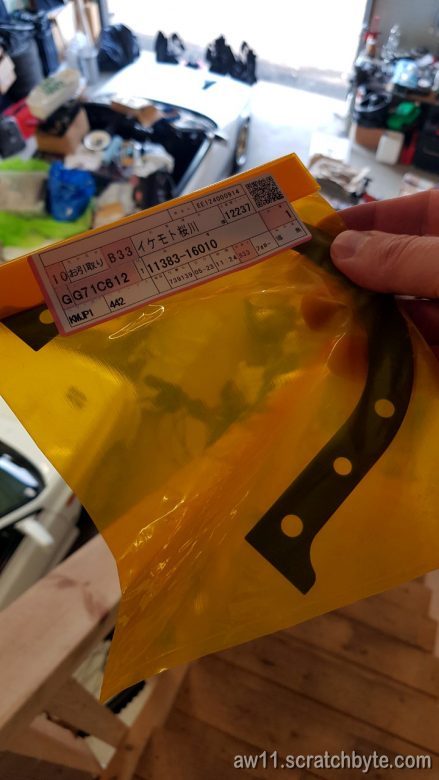

A japanese part for Toyota that isnt Denso! Arai electric, never heard of the company but presumably this is a quality spare.

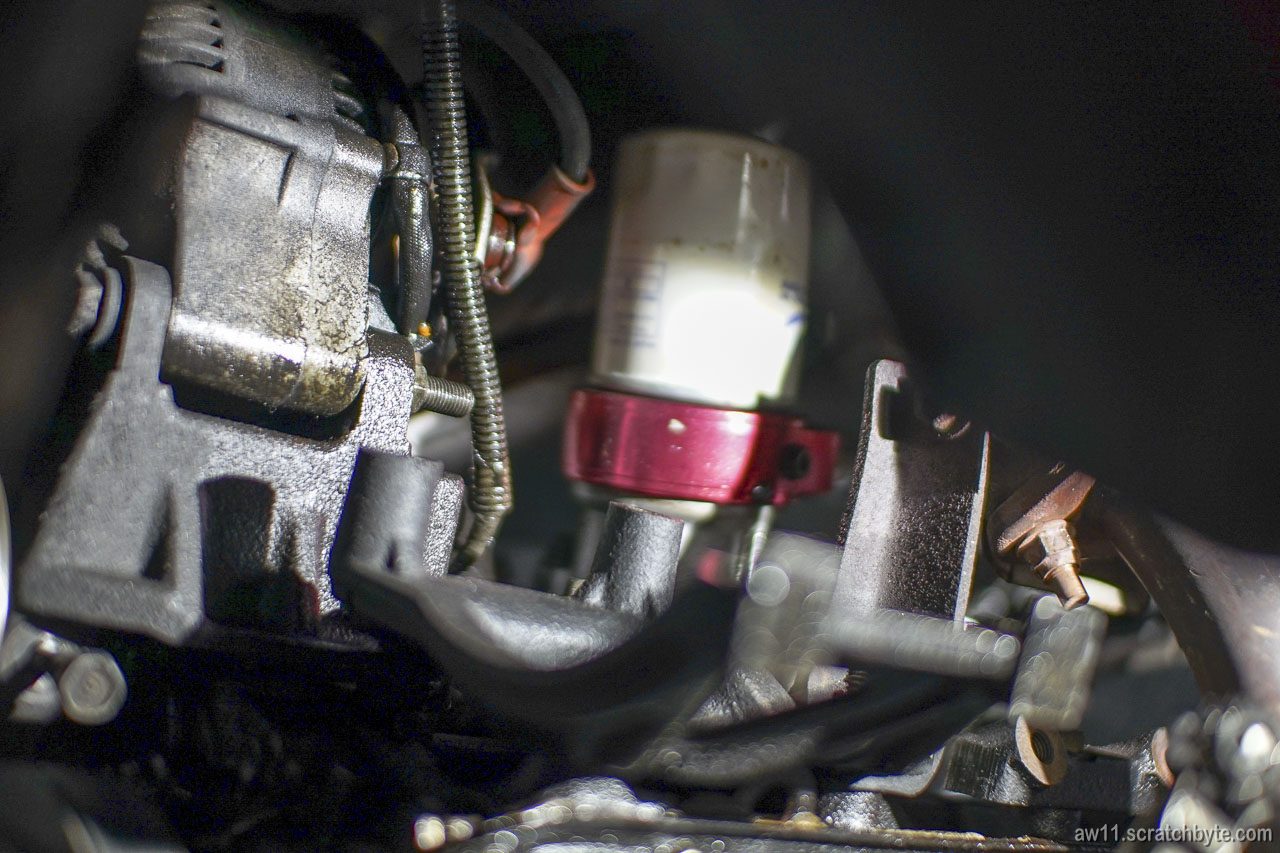

I guess oil, dirt and time got this alternator. Wonder if this is still rebuildable? Burn marks visible on top of the alternator, coming from under the heatshield.

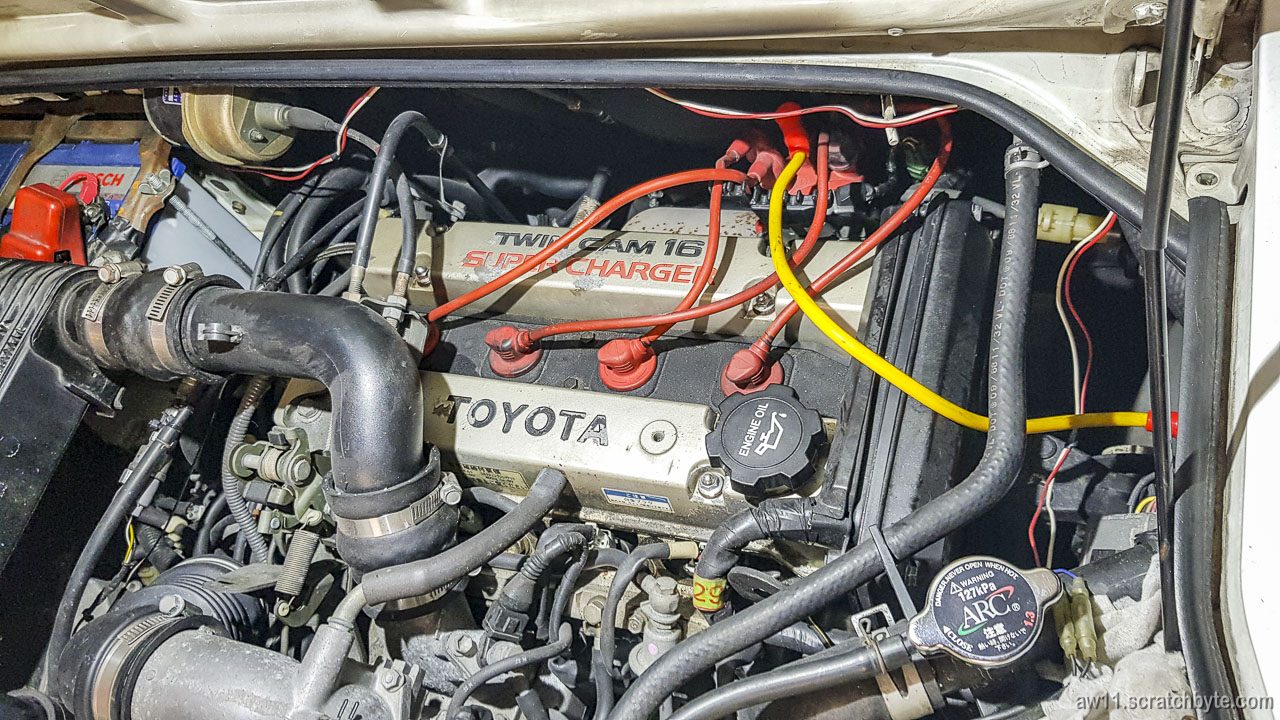

From above. Distributor without cap and rotor. There is still some oil on the heatshield. This is a wild guess, but when the boost builds up, there could be so much pressure inside cylinder head that it is pressurizing the distributor thru the worn shaft seal, then spraying the included oil around engine bay.

I better take the distributor off the engine at some point and examine it.

Old and used distributor cap, still in working order.

Old plug wires. Salvaged the quality Ultra wire that sits between distributor and coil.

After I noticed that something was wrong with the car (the smell, not charging and burn marks) I turned it off and started it couple of times. While turning on the power, the warning lights just briefly blinked and stayed off. I thought that something else was also affected, maybe a relay or a shorted wire.

To my relief, after the alt swap warning lights stayed on when the power was turned on. Seems like no shorted, melted or otherwise damaged electrics.

I’m not sure if the lights were acting before alternator caught fire, but I guess the lights were not supposed to indicate problems this way 😀

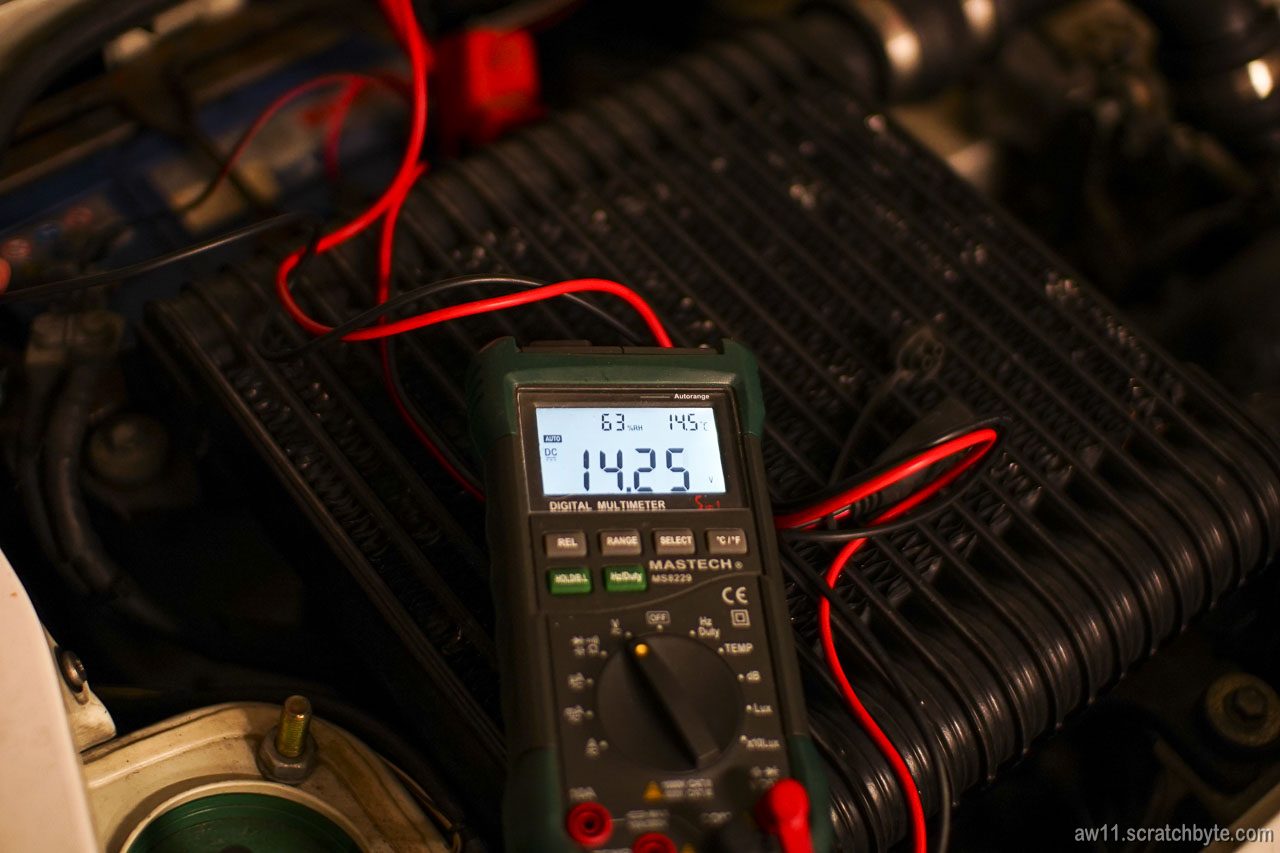

The pessimistic AEM voltage gauge is showing surprisingly high voltage.

I dont think Ive ever had this high charge voltage. Goody good 🙂 Runs well.